The task of finding the perfect shape of a real-world object that fulfills a given objective optimally appears in many disciplines, like interior design, building planning, or construction of machine parts. These tasks can be subject to considerations of functionality, cost-effciency, and aesthetics, as well as constraints relating to size, producibility, safety margins, etc. The great complexity and the presence of conflicting and hard-to-formalize goals have hitherto precluded automation of many design tasks and leave them in the hands of human designers and engineers.

There is, however, great potential to aid these processes computationally and to unlock difficult design tasks for a larger audience. This will not only provide faster work flows and enable the exploration of new design spaces, but it constitutes a necessary step towards the wide-spread application of personalized fabrication techniques like additive manufacturing. Low-cost 3d printing has been widely described as a disruptive technology and the herald of a new industrial revolution. These expectations have since been tempered by a reality which shows that availability alone is inconsequential unless accompanied by an innovation of supporting technologies.

The big challenge in making new fabrication techniques more useful is the development of a computational design methodology that relieves its users of low-level tasks like explicit 3d modeling and provides tools to create shapes from functional, aesthetic, and other high-level specifications. The overarching goal of this research area is to find new mathematical models and computational solutions fordesign tasks that are at this time tedious or impossible at all.

Publications

17 Publications found:

Bibtex, HTML (Advanced, Expert), JSON (with referenced objects), CSV, Permalink

Bachelor thesis

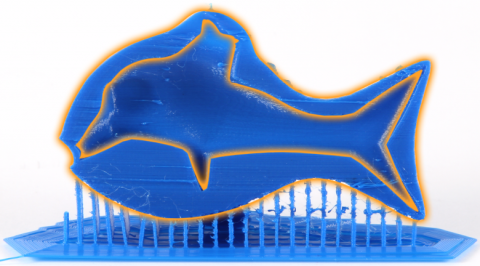

Bachelor thesis Image

Image

image

image paper preprint

paper preprint

image

image paper

paper

image

image Paper

Paper

poster

poster thesis

thesis

image

image

preprint

preprint video

video

thesis

thesis

paper_3MB

paper_3MB supplemental

supplemental

poster

poster

additional

additional fastforward

fastforward image

image preprint

preprint video

video

abstract

abstract eposter

eposter thumbnail

thumbnail video

video