Information

- Publication Type: Technical Report

- Workgroup(s)/Project(s):

- Date: May 2007

- Number: TR-186-2-07-06

- Keywords: DECT image fusion, local surface extraction, metrology, Dual Energy CT, dimensional measurement, variance comparison

Abstract

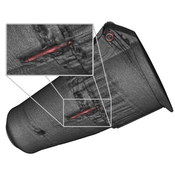

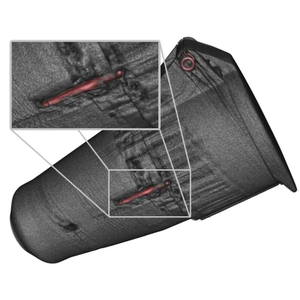

This paper describes a novel method for creating surface models of multi-material components using dual energy computed tomography (DECT). Application scenario for the presented work is metrology and dimensional measurement of multi-material components in industrial high resolution 3D X-Ray computed tomography (3DCT). The basis of this method is the dual source / dual exposure technology using the different X-Ray imaging modalities of a high precision micro-focus and a high energy macro-focus X-Ray source. The presented work aims at combining the advantages of both X-Ray modalities in order to facilitate dimensional measurement of multi-material components with high density material within low density material. We propose a pipeline model using image fusion and local surface extraction technologies: A prefiltering step reduces data inherent noise. For image fusion purposes the datasets have to be registered to each other. In the fusion step the benefits of each modality are combined. So the structure of the specimen is taken from the low precision, blurry, high energy dataset while the sharp edges are adopted and fused into the resulting image from the high precision, crisp, low energy dataset. In the final step a reliable surface model is calculated of the fused dataset, which locally adapts the surface model by moving surface vertices in the direction of the corresponding point normal to a position with maximum gradient magnitude. The major contribution of this paper is the development of a specific workflow for dimensional measurement of multi-material industrial components from high resolution industrial CT data. Several algorithms are extended to take two data sources with complementary strengths and weaknesses into account. The presented workflow is crucial for the following visual inspection of deviations.Additional Files and Images

Weblinks

No further information available.BibTeX

@techreport{TR-186-2-07-06,

title = "Surface Extraction from Multi-Material Components for

Metrology using Dual Energy CT",

author = "Christoph Heinzl and Johann Kastner and Eduard Gr\"{o}ller",

year = "2007",

abstract = "This paper describes a novel method for creating surface

models of multi-material components using dual energy

computed tomography (DECT). Application scenario for the

presented work is metrology and dimensional measurement of

multi-material components in industrial high resolution 3D

X-Ray computed tomography (3DCT). The basis of this method

is the dual source / dual exposure technology using the

different X-Ray imaging modalities of a high precision

micro-focus and a high energy macro-focus X-Ray source. The

presented work aims at combining the advantages of both

X-Ray modalities in order to facilitate dimensional

measurement of multi-material components with high density

material within low density material. We propose a pipeline

model using image fusion and local surface extraction

technologies: A prefiltering step reduces data inherent

noise. For image fusion purposes the datasets have to be

registered to each other. In the fusion step the benefits of

each modality are combined. So the structure of the specimen

is taken from the low precision, blurry, high energy dataset

while the sharp edges are adopted and fused into the

resulting image from the high precision, crisp, low energy

dataset. In the final step a reliable surface model is

calculated of the fused dataset, which locally adapts the

surface model by moving surface vertices in the direction of

the corresponding point normal to a position with maximum

gradient magnitude. The major contribution of this paper is

the development of a specific workflow for dimensional

measurement of multi-material industrial components from

high resolution industrial CT data. Several algorithms are

extended to take two data sources with complementary

strengths and weaknesses into account. The presented

workflow is crucial for the following visual inspection of

deviations.",

month = may,

number = "TR-186-2-07-06",

address = "Favoritenstrasse 9-11/E193-02, A-1040 Vienna, Austria",

institution = "Institute of Computer Graphics and Algorithms, Vienna

University of Technology ",

note = "human contact: technical-report@cg.tuwien.ac.at",

keywords = "DECT image fusion, local surface extraction, metrology, Dual

Energy CT, dimensional measurement, variance comparison",

URL = "https://www.cg.tuwien.ac.at/research/publications/2007/TR-186-2-07-06/",

}

paper

paper