Information

- Publication Type: Master Thesis

- Workgroup(s)/Project(s):

- Date: March 2008

- TU Wien Library:

- First Supervisor:

- Eduard Gröller

- H.P. Degischer

- M. Schobel

- Eduard Gröller

Abstract

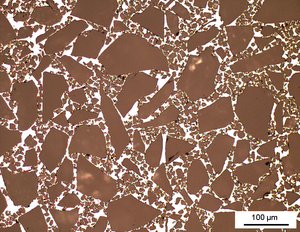

The expansion behavior of particulate reinforced AlSiC metal matrix composites (MMCs) during a thermal cycle shows anomalies at temperatures above 250°C, explained by viscoplastic matrix deformations and changing void volume fractions. Volumetric images of the sample acquired by synchrotron tomography at several temperatures between 30°C and 400°C are used to analyze the void kinetics. These high-resolution low-contrast 3D + T images are not aligned, thus only allowing quantitative comparisons over areas comprising many voids. Analysis of speci c voids at various temperatures was not feasible, due to the three-dimensional misalignment. We present a 3D registration approach based on mutual information that allows for sub-pixel accurate registration. A maximum intensity projection (MIP) may be used for a manual pre-alignment. Further software tools for the analysis of void kinetics of AlSiC provide linked views for 2D slices, 3D isosurfaces, volume rendering, as well as overlaid contours (isolines) of multiple images on an arbitrarily positionable cutting plane, and the calculation of a shape factor. By registering the volumetric datasets, we were able to visualize the shrinkage and expansion of a speci c void during thermal cycling between room temperature and 400°C and to analyze the change of quantitative properties of speci c voids{including volume, surface, shape factor|resulting from temperature changes.Additional Files and Images

Weblinks

No further information available.BibTeX

@mastersthesis{altendorfer-2008-vts,

title = "Void Tracking in SiC Particle Reinforced Al",

author = "Wolfgang Altendorfer",

year = "2008",

abstract = "The expansion behavior of particulate reinforced AlSiC metal

matrix composites (MMCs) during a thermal cycle shows

anomalies at temperatures above 250°C, explained by

viscoplastic matrix deformations and changing void volume

fractions. Volumetric images of the sample acquired by

synchrotron tomography at several temperatures between 30°C

and 400°C are used to analyze the void kinetics. These

high-resolution low-contrast 3D + T images are not aligned,

thus only allowing quantitative comparisons over areas

comprising many voids. Analysis of speci

c voids at various

temperatures was not feasible, due to the three-dimensional

misalignment. We present a 3D registration approach based on

mutual information that allows for sub-pixel accurate

registration. A maximum intensity projection (MIP) may be

used for a manual pre-alignment. Further software tools for

the analysis of void kinetics of AlSiC provide linked views

for 2D slices, 3D isosurfaces, volume rendering, as well as

overlaid contours (isolines) of multiple images on an

arbitrarily positionable cutting plane, and the calculation

of a shape factor. By registering the volumetric datasets,

we were able to visualize the shrinkage and expansion of a

speci

c void during thermal cycling between room temperature

and 400°C and to analyze the change of quantitative

properties of speci

c voids{including volume, surface, shape

factor|resulting from temperature changes.",

month = mar,

address = "Favoritenstrasse 9-11/E193-02, A-1040 Vienna, Austria",

school = "Institute of Computer Graphics and Algorithms, Vienna

University of Technology ",

URL = "https://www.cg.tuwien.ac.at/research/publications/2008/altendorfer-2008-vts/",

}

paper

paper