Information

- Publication Type: Master Thesis

- Workgroup(s)/Project(s):

- Date: January 2009

- TU Wien Library:

- Diploma Examination: January 2009

- First Supervisor:

Abstract

Non-destructive testing (NDT) is a key aspect of present day engineering and development

which examines the internal structures of industrial components such as

machine parts, pipes and ropes without destroying them. Industrial pieces require

critical inspection before they are assembled into a finished product in order to

ensure safety, stability, and usefulness of the finished object. Therefore, the goal of

this thesis is to explore industrial Computed Tomography (CT) volumes, with the

goal to facilitate the whole quantification approach of the components at hand by

bridging the gap between visualization on the one hand, and interactive quantification

of features or defects on the other one.

The standard approach for defect detection in industrial CT builds on region growing,

which requires manually tuning parameters such as target ranges for density and size,

variance, as well as sometimes also the specification of seed points. To circumvent

repeating the whole process if the region growing results are not satisfactory, the

method presented in this thesis allows interactive exploration of the parameter

space. The exploration process is completely separated from region growing in

an unattended pre-processing stage where the seeds are set automatically. The

pre-computation results in a feature volume that tracks a feature size curve for

each voxel over time, which is identified with the main region growing parameter

such as variance. Additionally, a novel 3D transfer function domain over (density,

feature size, time) is presented which allows for interactive exploration of feature

classes. Features and feature size curves can also be explored individually, which

helps with transfer function specification and allows coloring individual features and

disabling features resulting from CT artifacts. Based on the classification obtained

through exploration, the classified features can be quantified immediately.

The visualization and quantification results of this thesis are demonstrated on

different real-world industrial CT data sets.

Additional Files and Images

Additional images and videos

Additional files

Weblinks

No further information available.

BibTeX

@mastersthesis{fritz-2009-ieq,

title = "Interactive Exploration and Quantification of Industrial CT

Data",

author = "Laura Fritz",

year = "2009",

abstract = "Non-destructive testing (NDT) is a key aspect of present day

engineering and development which examines the internal

structures of industrial components such as machine parts,

pipes and ropes without destroying them. Industrial pieces

require critical inspection before they are assembled into a

finished product in order to ensure safety, stability, and

usefulness of the finished object. Therefore, the goal of

this thesis is to explore industrial Computed Tomography

(CT) volumes, with the goal to facilitate the whole

quantification approach of the components at hand by

bridging the gap between visualization on the one hand, and

interactive quantification of features or defects on the

other one. The standard approach for defect detection in

industrial CT builds on region growing, which requires

manually tuning parameters such as target ranges for density

and size, variance, as well as sometimes also the

specification of seed points. To circumvent repeating the

whole process if the region growing results are not

satisfactory, the method presented in this thesis allows

interactive exploration of the parameter space. The

exploration process is completely separated from region

growing in an unattended pre-processing stage where the

seeds are set automatically. The pre-computation results in

a feature volume that tracks a feature size curve for each

voxel over time, which is identified with the main region

growing parameter such as variance. Additionally, a novel 3D

transfer function domain over (density, feature size, time)

is presented which allows for interactive exploration of

feature classes. Features and feature size curves can also

be explored individually, which helps with transfer function

specification and allows coloring individual features and

disabling features resulting from CT artifacts. Based on the

classification obtained through exploration, the classified

features can be quantified immediately. The visualization

and quantification results of this thesis are demonstrated

on different real-world industrial CT data sets.",

month = jan,

address = "Favoritenstrasse 9-11/E193-02, A-1040 Vienna, Austria",

school = "Institute of Computer Graphics and Algorithms, Vienna

University of Technology ",

URL = "https://www.cg.tuwien.ac.at/research/publications/2009/fritz-2009-ieq/",

}

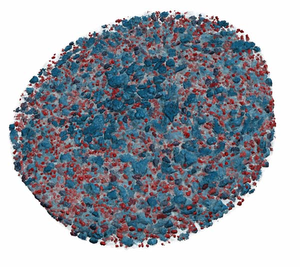

image

image paper

paper